Automation of the loading and unloading of tugger trains

WINKEL tugger train - Automated loading and unloading of tugger trains

WINKEL introduces a innovative solution for automating the loading and unloading of tugger trains - the WINKEL tugger train.

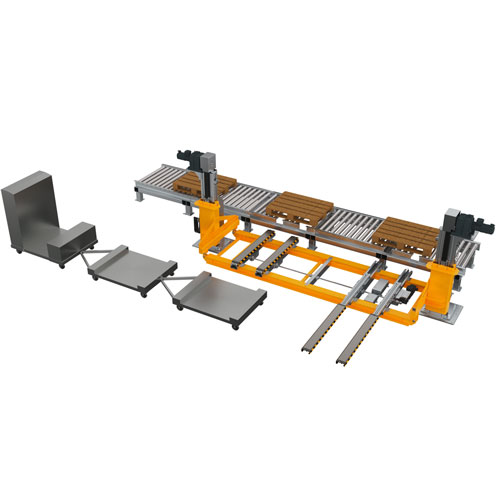

The new WINKEL tugger train sets new standards in terms of efficiency and flexibility in material flow. It was specially designed for the automatic loading and unloading of tugger trains with payloads from 0.1 to 10 tonnes. The system is suitable for both single load carriers and multi-load carriers at the same time.

The WINKEL Tugger trains trains are characterised by their versatility. In addition to the use of lifting systems with telescopic forks, gantry systems with adjustable forks are also possible. WINKEL thus offers a solution that can be individually adapted to the respective requirements of the customer.

Another decisive advantage is the compact design of WINKEL tugger trains. They allow space-saving use in production and storage areas, which can significantly increase the efficiency and productivity of operations.

WINKEL is proud to be able to make a further contribution to the optimisation of industrial logistics processes with this innovative solution. The WINKEL tugger train is proof of the company's commitment to always offer its customers the most advanced and reliable solutions.

For more information about WINKEL tugger trains, please visit our "Tugger trains" website or contact our sales team.

WINKEL is the market leader in heavy duty linear guidance and an experienced manufacturer of high quality motion and positioning systems in the field of linear and handling technology.