The right lifter for every requirement

To meet intralogistics requirements within production processes as well as handling tasks during actual production, the Winkel company offers a wide range of lifting systems.

Innovative, economically dynamic - More flexibility with the 7th axis!

In times when direct cooperation between humans and robots is becoming more and more important and robots work directly with humans without a protective enclosure, the WINKEL Cobot-Track can expand the working range of collaborating robots without much effort.

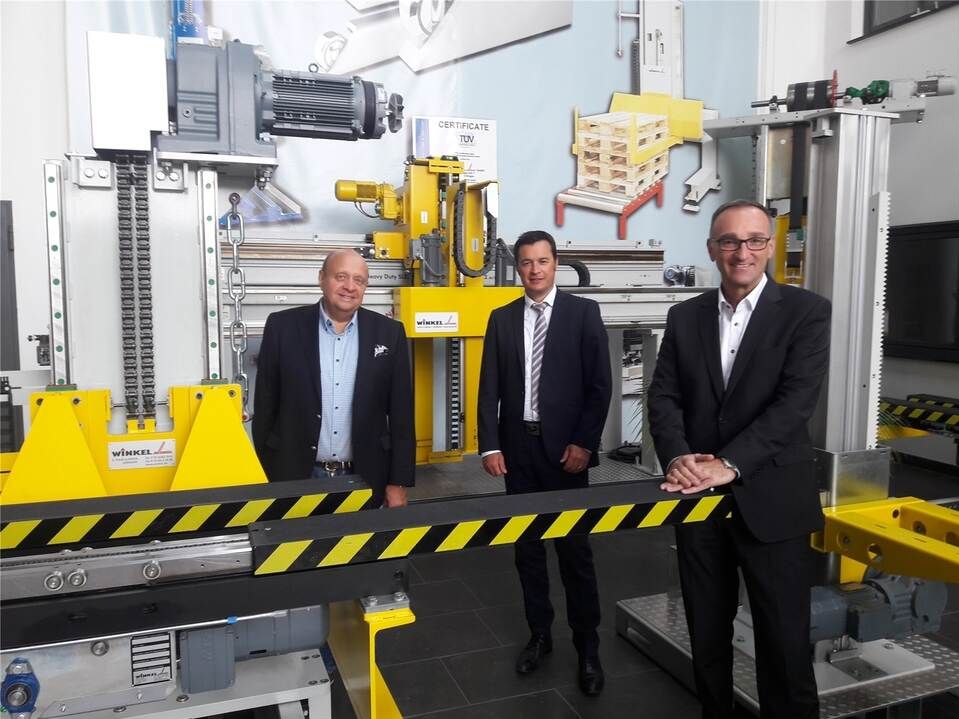

Family business Winkel founded in Illingen 40 years ago

What do the World Trade Center (WTC) Transportation Hub in New York, the Lidl&Schwarz beverage warehouse and the Bolshoi Theater in Moscow have in common? Technology from the Illingen-based company Winkel is used there.

Candy manufacturer Zile is modernizing its warehouse technology.

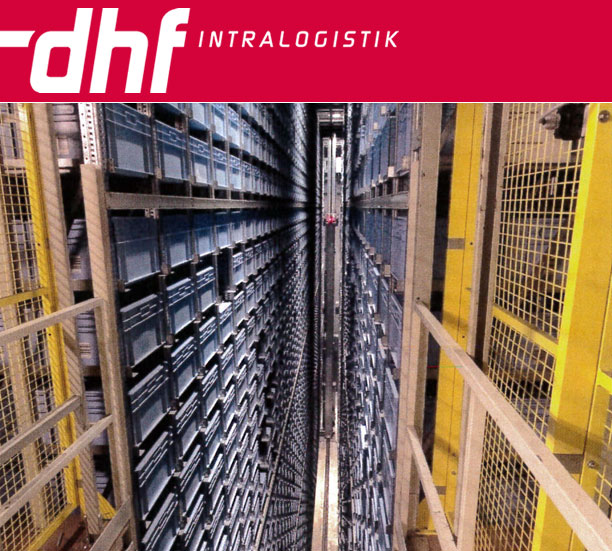

To increase production output, the Swiss candy manufacturer Zile decided to modernize its 20-year-old storage technology. Two Colibri storage and retrieval machines from Winkel are now used in the container store.

With the Colibri stacker, Zile was able to significantly increase throughput and make optimal use of the space in the warehouse.

The SR Storage and Retrieval revolution from WINKEL

Our modular system is used, for example, for the standard stacker Colibri and Puma.

When developing them, we asked ourselves how the customer could make optimum use of the available space. We also asked how to reliably increase throughput and save energy. Up to now, the usual answers from the market have been limited to an evolution of small steps - here, a few percent can be saved by saving a few millimeters. The revolution comes from us: The new WINKEL-RBGs Colibri and Puma beat all standard machines on the market by far.

Scientists at the University of Stuttgart are developing a method for manufacturing graded concrete components.

Scientists at the University of Stuttgart are developing a method for producing graded concrete components. Its many and varied applications make concrete indispensable. At the same time, however, it is also the cause of considerable emissions: The production of cement, the basic material for concrete, causes annual CO2 emissions that are three to four times higher than those of all air traffic worldwide. The reason: The raw material, which consists largely of limestone, is burned in blast furnaces at 1,400 to 1,450 degrees Celsius and often with fossil fuels. When it cools down, the carbon dioxide bound in the lime is released, the second largest source of CO2 after combustion.

The company Hauraton decided to use storage and retrieval machines from Winkel. With the shuttle storage solution and the efficient WINKEL S/R machines, the storage capacities were significantly increased.

Hauraton commissions around 11,000 deliveries per year at its Ötigheim site, and around 9,000 pallets leave the warehouse every month. WINKEL GmbH, the component and system supplier from Illingen in Württemberg is the market leader for heavy duty linear systems and has successfully implemented numerous projects in handling technology worldwide. As a long-standing partner of general contractors and system providers, Winkel not only offers a comprehensive standard range of products, but also individually manufactured special solutions to reliably solve special challenges. "With the shuttle storage solution and the efficient WINKEL S/R machines, we have significantly increased our storage capacity on the available space," says Michael Schenk. "The automation has enabled us to achieve the desired efficiency of our processes and significantly increased throughput with reduced personnel costs".

At the LogiMAT 2015, the company WINKEL wants to underline its competence in the field of automatic storage and order-picking technology. In addition, the Fast Pick Station will be presented as a two-storey solution.

At the trade fair stand in Stuttgart, the intralogistics specialist WINKEL will be showing, among other things, the dynamic and energy-efficient Colibri and Puma pallet stacker as well as the Fast Pick Station for ergonomic palletizing, depalletizing and order picking.

With the Colibri SRM models for container and cartons and the Puma for pallets and box pallets, WINKEL offers two standard solutions that are particularly impressive thanks to their slim design, practically vibration-free behaviour and high acceleration. WINKEL machines can be built significantly lighter and stiffer, making them much more dynamic, the company states. They achieve a throughput 25 percent higher than competitive products - and consume much less energy, WINKEL praises the advantages. They also make better use of the available storage volume thanks to their unique braking system and compact design. Warehouse operators and system integrators can thus accommodate more shelving panels and levels in the same space and at the same height.

SEW-Eurodrive: Driving and safety systems for S/R machines.

Density packaging and handling performance are the two parameters, which are in the focus of storage operators. This is what the intralogistics providers adjust with their new and advanced developments. One current example is the new storage and retrieval machine "Colibri" by WINKEL GmbH in Illingen. Thanks to sophisticated design of the S/R machine, which is lighter and with a smaller approach and do not require buffer. Servo drive technology and a sophisticated safety concept of SEW Euro Drive enable these technical progress.