How can warehouse space be optimized – without wasting space, while minimizing buffer zones for pallet handling or staging?

WINKEL, can offer solutions to storage, retrieval and warehouse utilization to help streamline workflow, and systems Integration. WINKEL – Partner for work flow and storage solutions.

The revolutionary new Colibri standard storage and retrieval systems for custom containers or cardboard cartons. They will help maximize throughput, minimize storage space, and

eliminate staging or buffer zones.

Maximize throughput, minimize storage space, and eliminate staging or buffer zones.

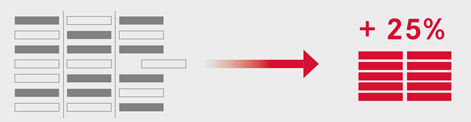

The WINKEL small parts COLIBRI system achieves a top acceleration of 5 m/s², (16 Ft/s²) and operates at 6 m/s (19 Ft/s) smoothly, unlike most other systems. Quick vibration-free acceleration and operation allows improved throughput of 25 % over conventional storage management systems.

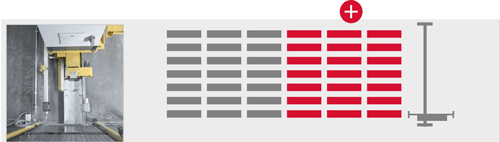

Thanks to our innovative brake and security system, no hydraulic buffers are required on both sides. More space for additional racks.

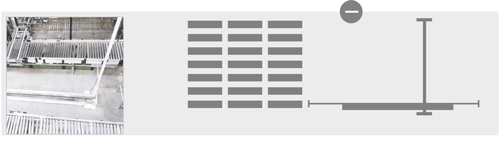

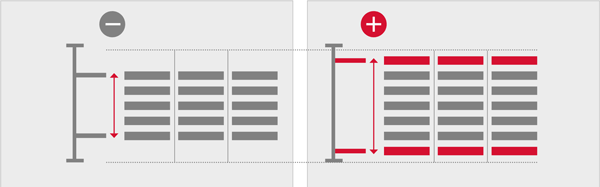

WINKEL Storage and Retrieval Systems are designed to maximize the storage space due to the compact nature of the components and drive. The hoist and load suspension design minimizes the lower and upper travel dimensions allowing additional storage space.

| Conventional Storage and retrieval System | WINKEL Storage and retrieval System | |

|---|---|---|

| Total weight | High, to absorb vibrations | Approx 30 % less weight |

| Acceleration | Low due to heavy system weight | High, thus up to 25% more throughput |

| Energy consumption | High due to high system weight | Approx 30 % less due to low weight |

| Construction length | Long due to hydraulic buffer zones | Significantly shorter thus, space for up to 5 more racks |

| Total time per entry- and retrieval process | 53 s | 47 s |

| Double operations per hour | 64 | 76 |

| Container per hour | 128 | 152 |