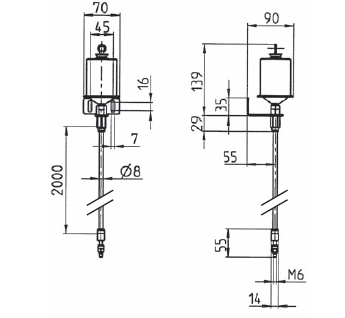

Type: 3.063

Heavy Duty WINKEL-Bearing

Advantages Heavy Duty WINKEL-Bearing Type 3.063

- Maximum resistance against dirt for heavy duty applications in the building material industry, foundry and mining industry

- Radial bearings relubricateable from face side

- Axial bearings are shock resistant ball bearings with 2 RS seals, lubricated for life

- Axial adjustment with washers

- For high speed application up to 2 m/sec

- Will be delivered 1 pc. grease nipple M6 x 1, O-ring and 2 pcs washers 0,5 mm

Heavy Duty WINKEL-Bearing |

Type 3.063

Article No. 200.216.306

Login for CAD download

Register CAD download

Note

External content is loaded

The 3D model is created and made availiable by TraceParts S.A.. Cookies and third-party cookies from Google Analytics are used, if you agree, you can activate the content by clicking the "Activate content" button.

| Type | D -0,1mm | A mm | B mm | C mm | E mm | F mm | G mm | H mm | I mm | J |

|---|---|---|---|---|---|---|---|---|---|---|

| 3.063 | 149,0 | 265,0 | 150 | 78,4 | 190 | 20 | 100 | 158 | 132,5 | M16 |

legend | Heavy Duty WINKEL-Bearing

A = Total length, B = Overall width, C = Overall heigth without sealing plates, E = Panel length, D = Outer diameter, Tollerance -0.1 mm, F = Panel thickness, G = Distance threaded holes, H = Bearings spacing, I = Position of radial bearing, J = Thread size

| Type | FR kN | FA kN | Weight kg | Profile | Washer t=0.5 mm |

|---|---|---|---|---|---|

| 3.063 | 59,20 | 18,50 | 13,6 | 6 NbV | DS-6-Q-LUB-0,5 |

legend | Heavy Duty WINKEL-Bearing

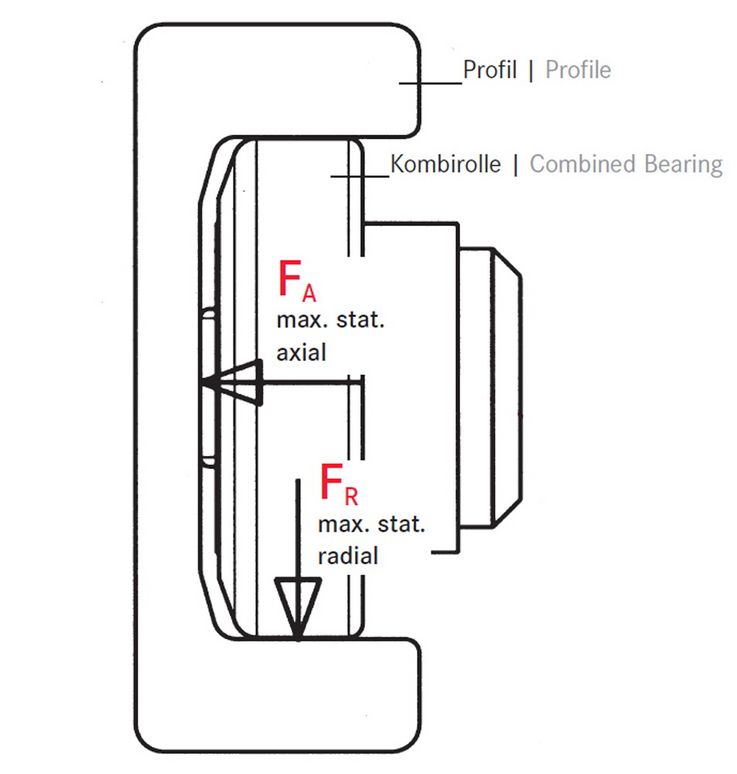

FR = Load capacity radial bearing max. allowable force between bearing and profile, FA = Load capacity axial bearing max. allowable force between bearing and profile

General Advice WINKEL Bearings

With our WINKEL Bearings vertical and horizontal movements on machines and lifting devices can be solved economically.

Advantage of the WINKEL Bearing system:

- Reduces your designing and production costs

- Can take up high radial and axial loads

- Strong profiles for high stat. and dynamic loads

- Best dispersion of forces in the profiles

- Longer lifetime for bearings and profiles

- Economical assembling by welding bolt

- Bearing components are easily exchangeable

Dimensions

- For the dimension of bearing and profile, the maximum allowable load F [N] max. stat. should be confirmed. See below calculation of of the bearing forces

Relubrication

- Our Winkel bearings are full complement cylindrical rollers which are lifetime lubricated for one shift and unsteady operation. Due to many years of experience we can assure you that for these kinds of use there will be no reduction of lifetime at normal applications.

- For applications such as for example in warehouses and machine halls a light surface conservation with commercial spray oil will be sufficient and in addition, a regular relubrication every 6 months.

- For extension of life-time the Winkel bearings 4.054 up to 4.064 are relubricateable. Generally, the relubrication holes are closed with threaded plugs M6. The bearings are delivered without grease nipple.

- In case of special environmental conditions such as dust, incur of dirt, moisture, outdoor operations, temperatures over 40 degrees, frequent load changes (continuous operation) and heavy duty the bearings should be relubricated at least one time per month. For this we would recommend to you to use our lubrication system Winkel Combi-Lub 1 or a central lubrication system.

- Bearings are lubricated with grease grade 3 (e.g. Shell Gadus S2 V100 3)

Working up

- For welding operations on WINKEL Bearings with a diameter less than 100 mm, all bearing components must be disassembled.

- WINKEL Bearings with an outer diameter more than 130 mm should be welded on both sides of the bolt.

- After the assembling of the bearings, or after the adjusting operation, the front side screws should be secured with loctite.

- To avoid cracks in the welded joints please use welding electrodes and cored wire for unalloyed steel. For example electrode: E 42 5 B 42 H 10 according DIN EN 499. For example cored wire: T 42 4 B C 3 H5 / 7 42 4 B M 3 H5 according DIN EN 758.

- The guide ways in the profiles should be lightly greased and not painted.

Special designs

- Special bolts are available for WINKEL Bearings of type (PR) 4.072 (P) to (PR) 4.080 (P).

System solutions

- We construct and manufacture complete lift- and handling units according to customer needs. Constructions with CAD and a progressive production enables high flexibility in achieving complete solutions in the field of handling systems and automation.

Tolerances

- For all not tolerated dimensions counts ISO 2768 - m

With our WINKEL Bearings vertical and horizontal movements on machines and lifting devices can be solved economically.

Advantage of the WINKEL Bearing system:

- Reduces your designing and production costs

- Can take up high radial and axial loads

- Strong profiles for high stat. and dynamic loads

- Best dispersion of forces in the profiles

- Longer lifetime for bearings and profiles

- Economical assembling by welding bolt

- Bearing components are easily exchangeable

Technical details:

- Outer rings are made from case-hardened steel 20 CrMnTi hardened at 58-62HRC

- Inner rings are made from bearing steel 100 Cr 6 hardened at 58-62 HRC

- Cylindrical rollers have flat ground heads, made of 100 Cr 6 steel hardened at 60 – 65 HRC

- Welding bolts are made from C20 (Material no. 1.1151)

- Bearings from 4.054 to 4.064 are relubricateable

- Working temperature of WINKEL Bearings is -20 °C up to +100°C.

- WINKEL High Temperature Bearings can be used at max. +250 °C environmental temperature.

- The max. speed for WINKEL Bearings in steel version is 3m/s. For VULKOLLAN® and POLYAMIDE kind of bearings is the max. speed 6 m/s.

- The clearance between axial bearing and inner side of the profile should not exceed 0,5 mm.

- Bolt tolerance –0.05 mm

- Bearings are lubricated with grease grade 3 (e.g. Shell Gadus S2 V100 3)

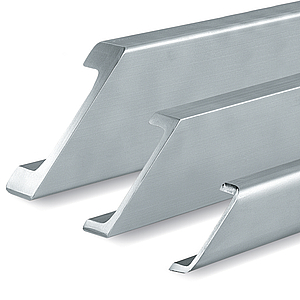

Suitable profiles

for

Type 3.063

"

Standard 6 NbV

,

PG 6 NbV

"

Technical details Standard 6 NbV | Article No. 113.016.000

| m | A | lx | Wx | ly | Wy | ey | Lmax |

|---|---|---|---|---|---|---|---|

| 52,3 kg/m | 66,6 cm2 | 3430,2 cm4 | 340,5 cm3 | 270,0 cm4 | 57,2 cm3 | 2,4 cm | 12m |

legend | Resistance Moments

Ix = surface moment, Iy = surface moment, Wx = resistance moment, Wy = resistance moment, m = mass, A = surface, ey = distance measure of the y-angle, Lmax = Maximum production length

Technical details PG 6 NbV | Article No. 113.021.006

| A* mm | B* mm | C mm | D mm | E* mm | F mm | G | Lmax |

|---|---|---|---|---|---|---|---|

| 201,5 | 69 | 177,8 | 150,1 ± 0,5mm | 17,2 | 30 | M16 | 12m |

legend | Resistance Moments

Ix = surface moment, Iy = surface moment, Wx = resistance moment, Wy = resistance moment, m = mass, A = surface, ey = distance measure of the y-angle, Lmax = Maximum production length

The profile is fine straightened*!

*The straightness for fine straightness profiles is ± 0,3 mm per meter, Standard profiles ± 1,0 mm per meter.Corrosion protection for profiles

Following coating are available:

Chemical galvanized

- All steel profiles with lengths up to 3 m are available in white or yellow galvanized version on request.

Plasma galvanizing

- All WINKEL profiles with lengths up to 12 m are available in plasma galvanized version. Completely welded constructions with our profiles are available in coated version, independent from their size. Plasma galvanized surfaces are superior to normal zinc coatings. The thickness of the coatings vary from 0,1 to 0,3 mm dependent of the use in land- or offshore atmosphere.

The usage of WINKEL Bearings on the raceway do not crack off the coating.

Login for CAD download

Register CAD download

Note

Login for CAD download

Register CAD download

Note

Lubrication System for Type 3.063

Exchange kit for Combi-Lub 1 WINKEL Exchange Kit WHF 04

Article no. 051.060.101

Content:

- Activator (6 months red, 12 months grey)

- Lubrication system with high performance grease WHF 04

High performance grease for pre-filling WINKEL high performance grease WHF 04

Article no. 051.060.108

- 400 gr. Cartridge High performance grease WHF 04

Heavy Duty WINKEL-Bearing Type 3.063

Calculation of the bearing forces

Q = Load capacity (N)

L = Load distance to suspension point (mm)

A = Bearing distance (mm) recommended 500-1000 mm

NEW!

To avoid wear out in the profile which is not hardened, the pressure between bearing and profile should be max.

Pzul = 900 N/mm2 for NbV-profiles,

Pzul = 750 N/mm2 for all profiles except NbV-series.

Here indicated are Fmaxstat radial+axial for each bearing.

| Profiles | FR kN max. radial | FA kN max. axial |

WINKEL Bearing with fixed axial bearing |

WINKEL Bearing eccentric adjustable axial bearing |

WINKEL Bearing adjustable with shims | WINKEL radial Bearing |

WINKEL Bearing with OILAMIDE insert |

Heavy Duty WINKEL Bearing |

Adjustable WINKEL Bearing unit |

WINKEL Bearing with combined bolt | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U-profiles | I-profiles | U-profiles | I-profiles | U-profiles | I-profiles | ||||||||

|  |  |  |  |  |  |  |  |  |  |  |  |  |

| A | - | 1,00 | - | 3,10 | - | - | - | - | - | 4.052 P | - | - | - |

| S | - | 5,23 | - | 1,68 | - | 4.053 | - | - | - | - | - | - | - |

| (PR) 0 NbV | - | 10,30 | - | 3,20 | - | (PR) 4.054 | (PR) 4.454 | (PR) 4.072 | (PR) 2.054 | (PR) 4.072 P* | (PR) 3.054* | JC 4.054 | KB (PR) 4.072 P* |

| (PR) 1 NbV | 3018 NbV | 12,40 | 12,40 | 3,87 | 3,87 | (PR) 4.055 | (PR) 4.455 | (PR) 4.073 | (PR) 2.055 | (PR) 4.073 P* | (PR) 3.055* | JC 4.055 | KB (PR) 4.073 P* |

| (PR) 2 NbV | - | 12,90 | - | 4,00 | - | (PR) 4.056 | (PR) 4.456 | (PR) 4.074 | (PR) 2.056 | (PR) 4.074 P* | (PR) 3.056* | JC 4.056 | KB (PR) 4.074 P* |

| - | 3019 NbV | - | 12,90 | - | 4,00 | 4.057 | 4.457 | 4.075 | - | - | - | - | - |

| (PR) 3 NbV | 3020 Nb | 22,40 | 22,40 | 7,00 | 7,00 | (PR) 4.058 | (PR) 4.458 | (PR) 4.076 | (PR) 2.058 | (PR) 4.076 P* | (PR) 3.058* | JC 4.058 | KB (PR) 4.076 P* |

| - | 2912 NbV | - | 22,00 | - | 7,00 | 4.059 | 4.459 | 4.077 | - | - | - | - | - |

| - | 3100 NbV | - | 23,80 | - | 7,44 | 4.060 | 4.460 | 4.078 | - | - | - | - | - |

| (PR) 4 NbV | - | 23,80 | - | 7,44 | - | (PR) 4.061 | (PR) 4.461 | (PR) 4.0784 | (PR) 2.061 | (PR) 4.0784 P* | (PR) 3.061* | JC 4.061 | KB (PR) 4.0784 P* |

| (PR) 5 NbV | - | 33,90 | - | 10,60 | - | (PR) 4.062 | (PR) 4.462 | (PR) 4.079 | (PR) 2.062 | (PR) 4.079 P* | (PR) 3.062* | JC 4.062 | KB (PR) 4.079 P* |

| - | 3353 NbV | - | 26,00 | - | 10,60 | 4.062 | 4.462 | 4.079 | - | - | - | - | - |

| (PR) 6 NbV | - | 59,20 | - | 18,50 | - | (PR) 4.063 | (PR) 4.463 | - | (PR) 2.063 | (PR) 4.080 P* | (PR) 3.063* | JC 4.063 | KB (PR) 4.080 P* |

| (PR) 6 NbV | - | 39,50 | - | 18,50 | - | - | - | (PR) 4.080 | - | - | - | - | KB (PR) 4.080 |

| (PR) 7® NbV | - | 72,00 | - | 18,50 | - | (PR) 4.064 | (PR) 4.464 | - | (PR) 2.064 | (PR) 4.084 P* | - | - | - |

| (PR) 8 NbV | - | 91,80 | - | 23,70 | - | - | (PR) 4.085 | - | - | (PR) 4.085 P* | - | - | - |

| - | 10 | - | 41,71 | - | 13,91 | - | 4.089 | - | - | - | - | - | - |

| - | 16 | - | 58,00 | - | 19,40 | - | 4.090 | - | - | - | - | - | - |

| - | 18 | - | 84,00 | - | 28,00 | - | 4.091 | - | - | - | - | - | - |

| - | 28 | - | 101,50 | - | 33,90 | - | 4.092 | - | - | - | - | - | - |

| - | 36/42 | - | 139,40 | - | 46,50 | - | 4.093 | - | - | - | - | - | - |

| - | 50 | - | 192,00 | - | 57,70 | - | 4.094 | - | - | - | - | - | - |

* for max. axial load of WINKEL bearing please refer to the respective data sheet

Corrosion protection for WINKEL Bearings:

HARTCHROM coating

The HARTCHROM coating

Advantages HARTCHROM coating

Corrosion protection

- In contrast to conventional coatings, the low-crack hardchrome layer protects the base material permanently and sustainably against chemical and mechanical corrosion processes.

Adhesion

- The bond between the hardchrome layer and the base substrate is of a molecular nature. It is therefore almost impossible for the layer to lift off the base material.

Tribology/low friction coefficient

- The special spherical structure of the hardchrome surface helps to significantly reduce the coefficient of friction.

Tribology / Wear protection

- The HARTCHROM coating provides excellent wear protection, especially against overrolling loads. We will be happy to send you further technical information on request.