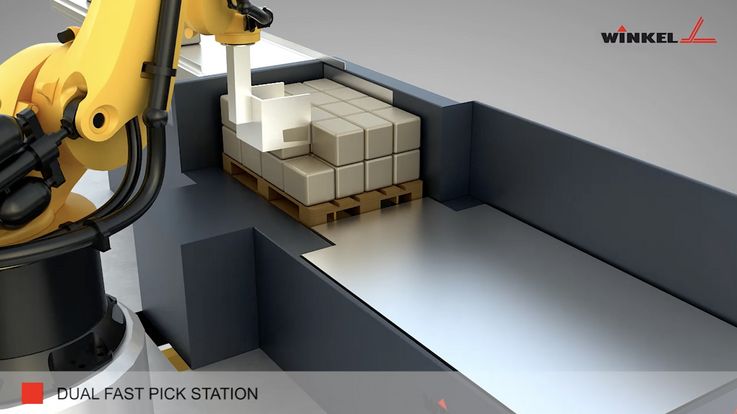

The DUAL FAST PICK station picking solution from WINKEL

Fully automatic loading of pallets and roller containers

To create the new DUAL FAST PICK station, Winkel’s engineers have optimized their proven twin-level FAST PICK picking solution. Users can now load pallets and roller containers fully automatically with a single system – without interrupting their work or needing to perform any conversions.

How does the DUAL FAST PICK Station work?

With the DUAL FAST PICK station, users can load both pallets and roller containers at one and the same machine without having to perform any conversion work or use additional equipment. The new system is based on the proven Winkel FAST PICK station and again boasts a twin-level design. Using this solution, picking can be performed for between 20 and 25 load carriers per hour – fully automatically and without interruptions.

- WINKEL have optimized their proven twin-level FAST PICK picking solution

- Between 20 and 25 load carriers per hour – fully automatically and without interruptions

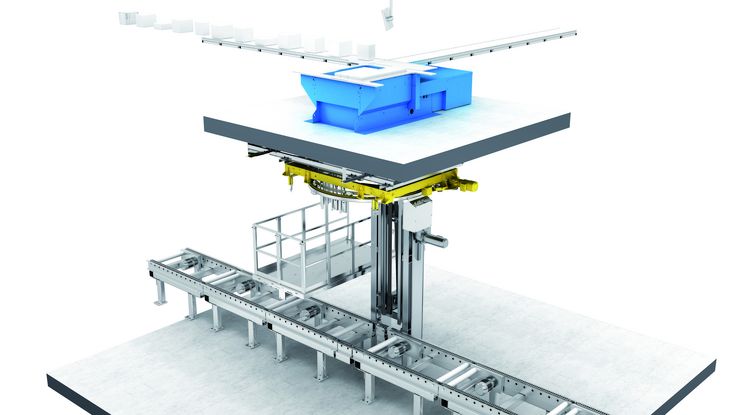

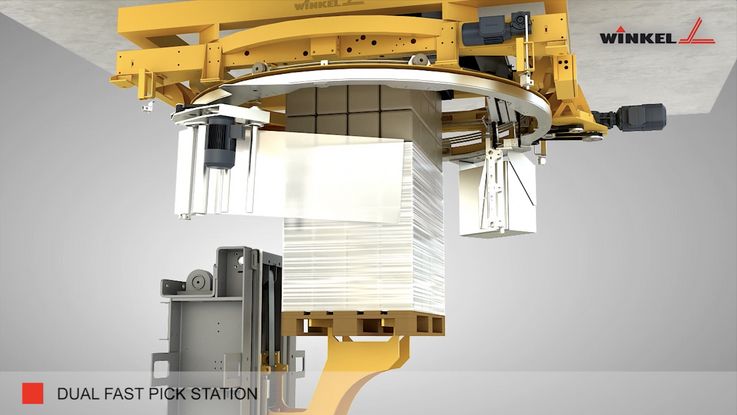

- Automatic shrink-wrapping and pallet buffer

The platform on the upper level of the DUAL FAST PICK station houses the picking table. A robot is supplied with various packages, packets and trays containing a mixture of goods via a conveyor system. It then combines these on an order-specific basis on the available pallets or roller containers. The load carriers can be lowered down one by one through a shaft in the platform. Below the shaft, there is an automatic shrink-wrapping unit. This wraps the fully laden load carrier with a tough, resistant film on its way to the conveyor system. This protects it during subsequent transport operations.

A pallet buffer and an intermediate floor ensure that the robot can operate without interruptions. The pallet buffer immediately supplies a new pallet as the full pallet is being lowered. If a roller container has to be loaded, the intermediate floor comes into play: A robot then picks the packages and packets until the order has been packaged. During this operation, an empty roller container travels up from the lower platform and is loaded with the goods. It is then lowered again, wrapped with film and passed on to the conveyor system.