Palletizing, (loading and unloading) and other material handling processes are typical tasks where goods are moved in the shortest time possible. Now, a WINKEL innovation combines high performance, efficient motion control and extreme reliability in the FAST PICK STATION.

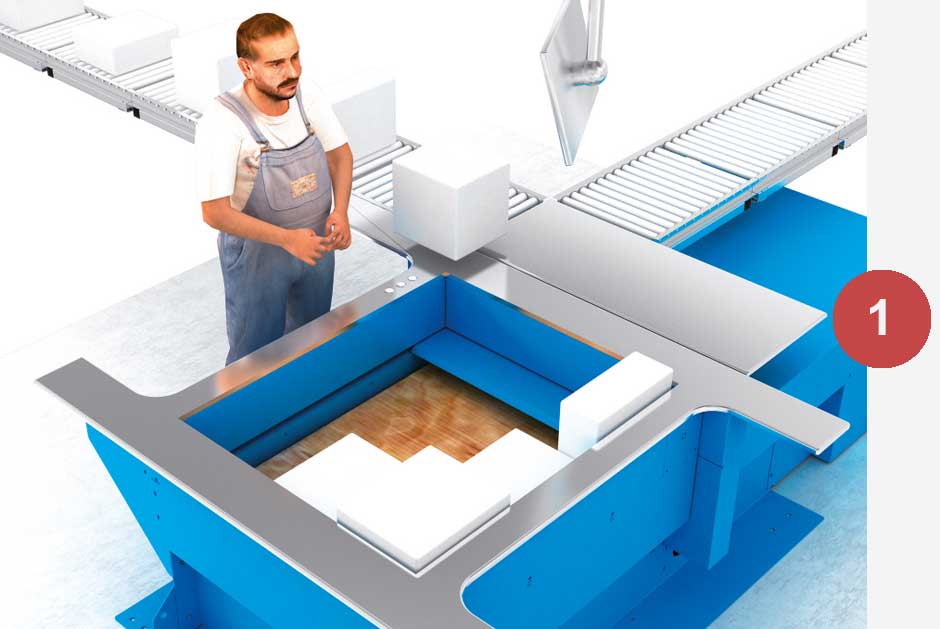

The FAST PICK STATION consists of a work station that processes, shrink wraps, stacks and conveys pallet ready

shipments quickly and efficiently. The goods are forwarded down through the shaft and shrink wrapped immediately,securing the goods for shipment.

The FAST PICK STATION can be easily integrated into existing conveying systems since it does not require a pit.

The FAST PICK STATION can be used with a number of applications, including unit conveying and package processing, e.g. automotive parts, food, textile, drug and other packaged goods.

Pallets with mixed goods can also be commissioned with the FAST PICK STATION without any problems.

Eine Palette wird auf dem Kommissioniertisch der FAST PICK STATION mit unterschiedlichen Waren beladen.

Diese werden einzeln oder auf Trays angedient, das Waren-Wirtschafts-System sorgt für die richtige Reihenfolge. Der Kommissionierer kann die Höhe der Palette immer individuell anpassen.

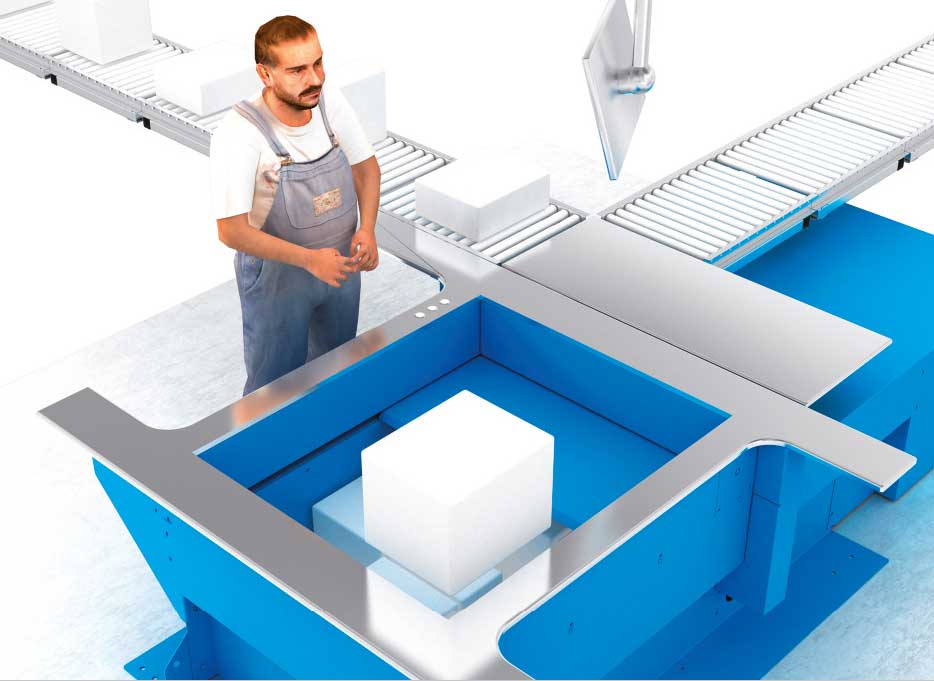

Ist die Palette fertig kommissioniert, wird sie automatisch über den Schacht abgesenkt. Die Schachtwände sorgen dafür, dass die Ladung stabil bleibt. Das ist besonders bei Paletten mit gemischten Waren wichtig.

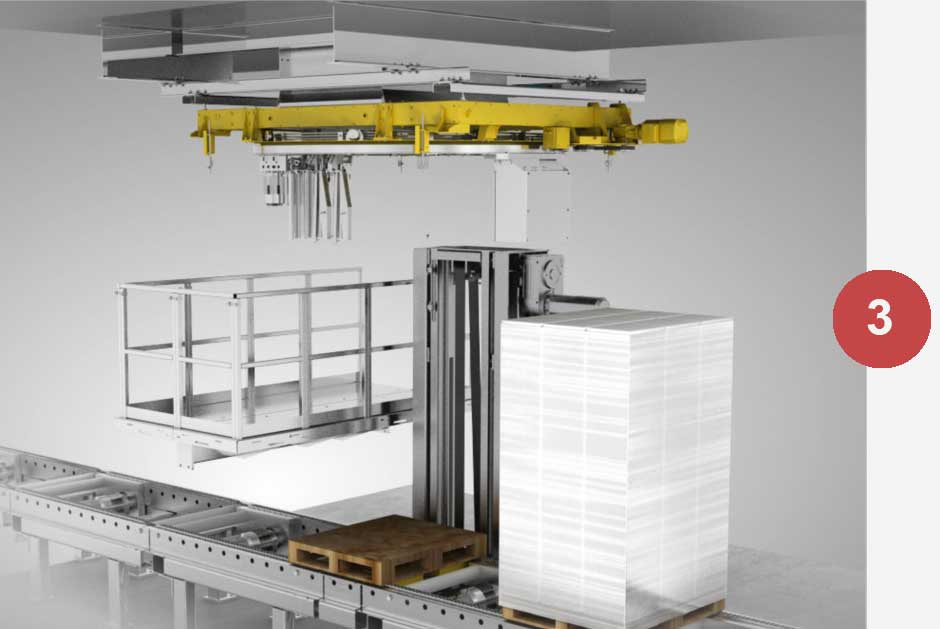

Ein Wickelstretcher umhüllt die Ladung sofort automatisch mit einer Folie, sobald die Palette den Schacht verlässt. So sind die Waren für den Transport vor Verrutschen und Verunreinigungen geschützt.

Die Fördertechnik transportiert die gestretchte Palette ab. Die nächste Palette wird bereitgestellt.

Optional kann der An-und Abtransport der Paletten auch manuell erfolgen. Die Wechselzeit zwischen zwei Ladungsträgern beträgt lediglich wenige Sekunden.

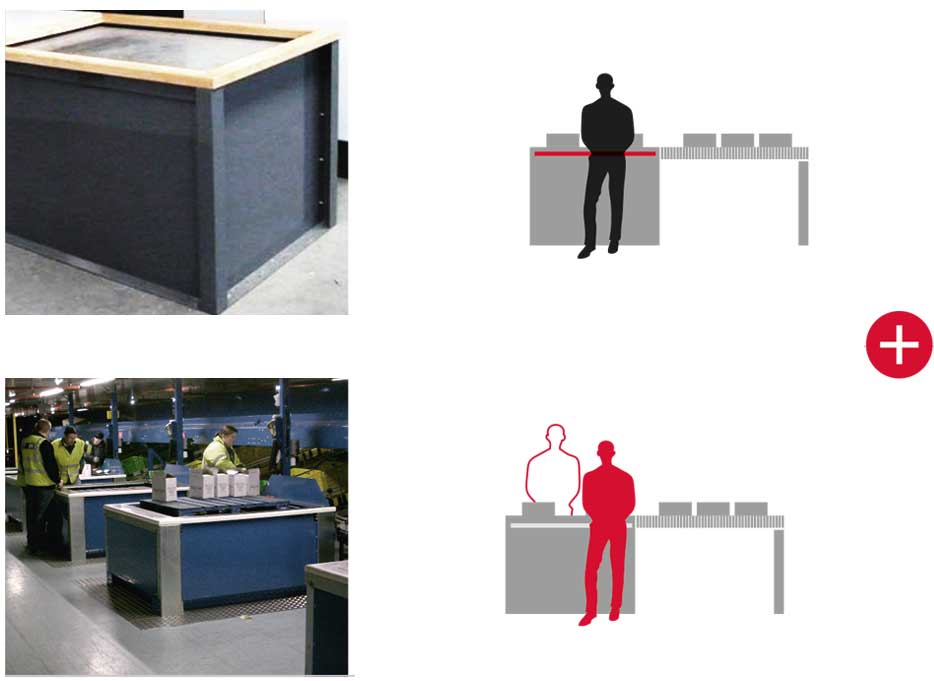

Effizienter arbeiten mit FAST PICK STATION Bis zu 800 Picks pro Stunde schafft ein einziger Mitarbeiter an einer FAST PICK STATION – einfach und bequem, ohne schweres Heben. Durch die enge Prozessführung wird die Fehlerquote beim Kommis - sionieren nahezu auf Null gesenkt.

Optional kann durch ein integriertes Puffersystem eine Leerpalette bereitgestellt werden auf der der Bediener weiterpalettieren kann. Paletten sind in wenigen Sekunden gewechselt.

Es gibt keine Unterbrechung während die vorherige Palette gestretcht wird.

Der Mitarbeiter kann sich die für ihn günstigste Arbeitsposition aussuchen.

Für noch mehr Effizienz können auch zwei Personen an einer FAST PICK STATION arbeiten.

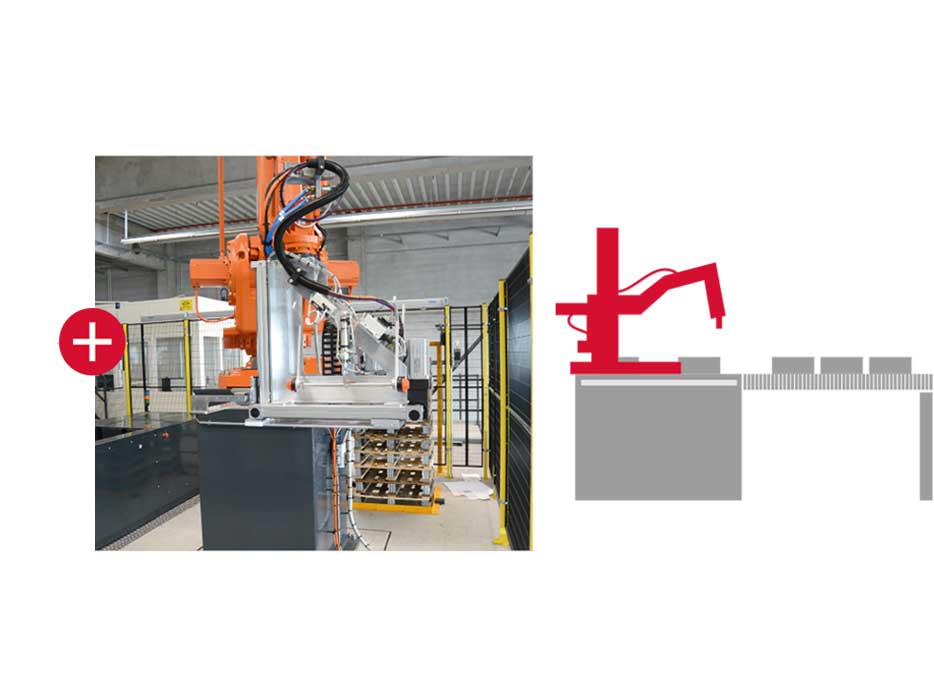

Die FAST PICK STATION ist auch für die vollautomatische Roboter- Kommissionierung erhältlich.

Das ist 100-prozentige Prozess-Sicherheit.

The FAST PICK STATION positions the carrier – pallets, roller container and crates – always at the optimal height. The staff must not lift the goods anymore, only move it horizontally – an enormous simplification! To ease the work more, the FAST PICK STATION can be combined with different lifting aids if desired..

Die FAST PICK STATION kann unterschiedliche Ladungsträger handhaben: Euro-Paletten, ½-Euro-Paletten, Industriepaletten, Rollcontainer, Gitterboxen…