WINKEL offers general contractors a wide range of plant and machinery

Whether lifting, moving, palletizing or picking - the tasks in intralogistics are manifold. Different transport solutions are necessary to handle dissimilar products as efficiently as possible. These must be adapted to the requirements of the products as well as the local conditions. Winkel therefore offers general contractors a wide range of options when selecting the appropriate equipment - precisely tailored to the specific requirements.

Up to 800 picks and about ten tons per hour

This includes the FAST PICK Station. The unit is two-storeyed: On the upper floor the picking table is located on a platform. Employees receive different packages, parcels and trays with mixed goods via a conveyor system and pick them order-related onto pallets waiting for them. Below the platform there is a shaft into which the pallet can be lowered bit by bit. This means that the work surface is always at the optimum height, and the personnel do not have to laboriously lift the often heavy packages, but only move them horizontally onto the load carrier. Up to 800 picks and thus about ten tons per hour are possible in this way. An automatic film stretcher is integrated in the shaft. Once a pallet is fully loaded, it is conveyed downwards and then wrapped in a resistant film to secure it for further transport. A special feature is the pallet buffer: The solution immediately provides an empty pallet parallel to the lowering of the full pallet. The fully packed pallet is transported from the shaft directly to a conveyor system. The station then deposits another empty pallet in the buffer - while work is carried out continuously at the top.

To unload incoming goods, Winkel offers depalletizing stations. They consist of a lifting system with a workstation that is particularly ergonomically designed. The depalletizing station W-DP1-1500 allows free access from all sides. The employee can easily access the goods. The station is suitable for all pallet formats, has a load capacity of 1,500 kilograms and runs with a belt drive. It can optionally be equipped with a safety catch. The W-DP2-1500 is a compact depalletizing station for optimal connection to existing conveyor technology - even where space is limited. The goods are loaded and unloaded with a hand pallet truck. The system allows continuous working during pallet change. The load capacity is also 1,500 kilograms.

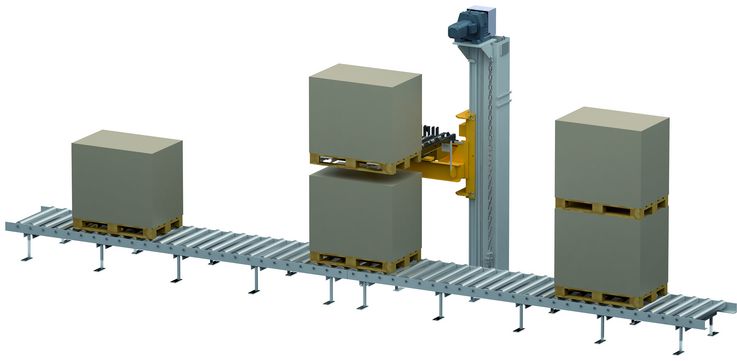

Lifters and traversing units ensure smooth processes

Modular chain and belt lifters move the palletized goods upwards particularly gently and efficiently. With a load capacity of 0.5 to six tons, they reach a lifting height of 40 meters. The lifting speed of the lifters is up to four meters per second. Lifting and travel units are also part of Winkel's portfolio, which also move the goods horizontally. They are ideally suited for multi-shift operation and can be integrated into existing conveyor systems. The lifting and traversing units are designed according to the modular principle and have a load capacity of between 0.5 and eight tons. The highly dynamic lifting systems are equipped with interception devices and modern safety technology. The load is picked up either by means of forks, telescopic forks or special gripping systems. Horizontally, the units are driven electromechanically. Winkel offers its customers lifting devices as one-, two- or four-column versions - with or without counterweight, depending on the requirements.

Easy handling of heavy loads

For pallet handling, Winkel offers a wide range of pallet storage and feeding stations, shifting solutions and pallet doublers for all standard formats worldwide. With the latter, individual load carriers can be easily stacked on top of each other. The system has a modular design and is equipped with rollers. The load capacity is between 0.5 and three tons. The load is picked up either by forks, telescopic forks or lateral pallet grippers. Pallet loading stations ensure safe pallet handling. Electromechanical drives move the goods vertically and transfer them onto roller conveyors. A pallet storage system such as the PSS 15 E is recommended, so that the empty pallets can be stored efficiently. It can store up to 15 pallets. The system is suitable for manual and fully automatic operation. The QVW transverse transfer carriage from Winkel also ensures highly dynamic pallet handling. The expandable system with rollers from Winkel moves the articles particularly efficiently from one workstation to the next. The QVW achieves a travel speed of five meters per second with a travel distance of up to 100 meters. The maximum load capacity is three tons.

With the storage and retrivial machines COLIBRI for totes and cartons and PUMA for pallets and mesh pallets, Winkel offers two innovative and proven standard solutions for high-bay warehouses, which convince with their slim design, practically vibration-free behaviour and high acceleration. Winkel units can be built much lighter and stiffer and are therefore considerably more dynamic. They achieve 25 percent higher throughput than competing products - and use much less energy. They also make better use of the available storage volume thanks to their unique braking system and compact design. Warehouse operators and system integrators can thus accommodate more racking bays and levels in the same space and height.

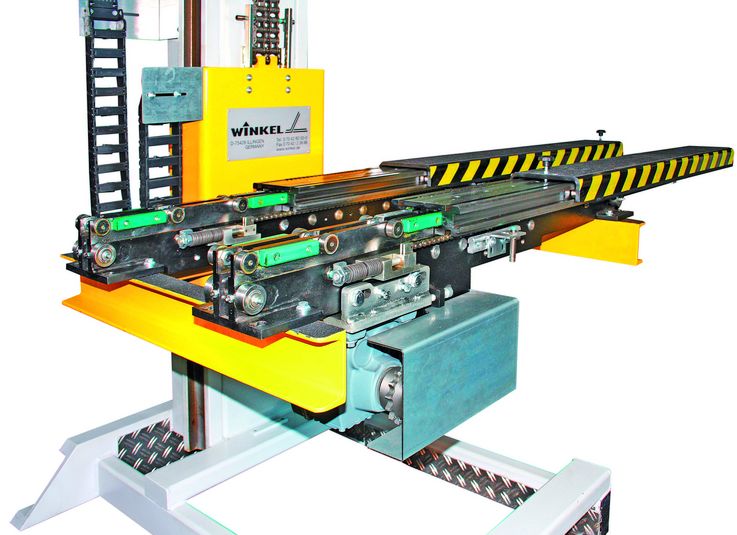

Telescopic solutions for every requirement

The Winkel range is rounded off by a wide range of telescopic tables and forks, which can be used to lift pallets for the respective processes. This offers angles in various designs for loads between one and two tons. Tables with reinforced telescopic forks are used, for example, when large strokes or low deflection are required. For double-deep applications, Winkel has a new version with either a single or double drive in its range. This is designed for a maximum load capacity of 1,500 kilograms. Telescopic tables with modified telescopic forks are also available in two different versions. All Winkel solutions feature high-strength steel profiles with precision roller guides. This enables particularly precise control. Positioning is carried out via the rotary encoder - either absolutely or step-by-step. To prevent the goods from slipping off the forks, they are provided with an anti-slip coating. In addition, Winkel also offers customers vertical telescopes that are hydraulically operated. These are designed for load capacities of up to eight tons. They are robust, low-maintenance and optimally suited for multi-shift operation. As standard, vertical telescopes are equipped with double load equipment with safety monitoring. This ensures smooth and safe processes. Winkel supplies suitable lifting carriages, support frames or special attachments according to individual customer requirements. Winkel telescopes are ideal for crane girders and are also used in the automotive industry.