Stack lifts

The stack lifts are predominantly designed for medium and half-size formats in PostPress processing.

By automatically lifting the cutted sheets , the operator can load them into the jogger or directly into the cutting machine at an ergonomically favorable working height.

The stack lift can also be used to accurately stack sheets after the cutting.

In the paper industry, stacking lifts are used to lift and lower printed sheets. In the paper industry, stacking lifts are used for lifting and lowering printed sheets. The stacking lift is driven hydraulically.

An adjustable light barrier is used in the automatic mode to automatically limit the stroke when stacking sheets.

Lowering is automatically stopped due to the stacked goods interrupting the light barrier. In addition, the stack lifts do not need to be anchored to the floor, so the location of the stack lift can be easily changed. For easy loading, the load platform of the stacking lift has a beveled front edge.

The stack lift has a safety device to protect the operator from foot injuries and provides the ideal conditions for ergonomic working at a comfortable working height. Due to the reduced stress of the operator, the productivity of the overall system remains constant.

The stack lift is lowered semi-automatically and is stopped in a safety zone approx. 17 cm above the floor. The stack lift can only be lowered to the floor by means of a separate pushbutton in tip mode.

This prevents injuries at the feet.

The stacking lift can be equipped with an optional stacking device for precise edge positioning of the stacked goods.

The stop of this stacking device can be adjusted variably from right to left to suit all formats and different print templates.

| ||||||

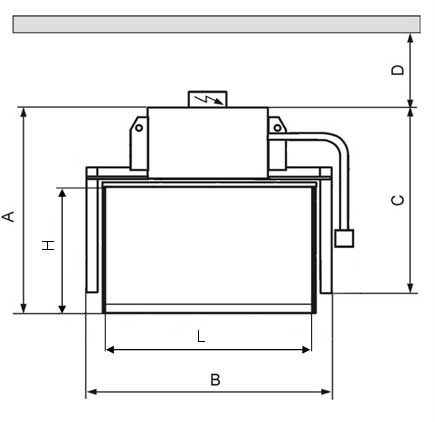

| Model | LW 450-2 | LW 1000-4 | LW 1200-4 | LW 1200-6 | LW 2000-6 | LW 2000-7S |

|---|---|---|---|---|---|---|

| A [mm] | 1045 | 1275 | 1275 | 1530 | 1590 | 1740 |

| B [mm] | 1060 | 1430 | 1430 | 1690 | 1720 | 1900 |

| C [mm] | 920 | 1200 | 1200 | 1400 | 1570 | 1720 |

| D [mm] | 800 | 800 | 800 | 800 | 800 | 800 |

| Weight [kg] | 450 | 550 | 570 | 700 | 1.115 | 1.200 |

|

Max. load capacity [kg] | 450 | 1.000 | 1.200 | 1.200 | 2.000 | 2.000 |

|

Paper format [mm] | 600 x 860 | 800 x 1.200 | 800 x 1.200 | 1.050 x 1.450 | 1.050 x 1.450 | 1.200 x 1.650 |

|

Clear opening of platform [mm] | 620 x 900 | 840 x 1.270 | 840 x 1270 | 1.090 x 1.520 | 1.090 x 1.520 | 1.240 x 1.790 |

| Height [mm] | 450 | 550 | 570 | 700 | 1.115 | 1.200 |

|

Total height [mm] (Lift in top position) | 1.960 | 1.960 | 1.960 | 1.960 | 2.120 | 2.120 |

|

Lifting height, max. [mm] | 850 | 850 | 850 | 850 | 900 | 900 |

|

Electrical power [kW] | 0,75 | 0,75 | 0,75 | 0,75 | 1,5 | 1,5 |

| Fuse [A] | 10 | 10 | 10 | 10 | 10 | 10 |

| Article number | 561.300.000 | 562.400.000 | 562.300.000 | 563.300.000 | 577.000.000 | 574.000.000 |

|

Article number with Stacking device | 561.300.111 | 562.400.111 | 562.300.111 | 563.300.111 | 577.000.020 | |

| Packing | IPPC crates and crate bases on request | |||||